We use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Learn more.

TK1-DX-3PH - DIRECT GAS FIRED TEMPERED MAKEUP AIR UNIT/DX

Gas-Fired Tempered Make-Up Air Unit with Direct Expansion/Maximum 1,850 CFM's, 208/230/460V, 3-Phase with Motorized Damper and a 10" Blower

- Gas-Fired Tempered Make-Up Air Unit with Direct Expansion handles a Maximum of 1,850 CFM's @ 0.5" wg ESP

- Max Temperature Rise of 100 Deg F. 129,600 BTU's, Natural Gas/LP Burner

- 5 Ton, Dual Circuit DX Cooling

- Adjustable CFM Range 1800-1850

- Fully Packaged Unit with 14 SEER Condensing Unit(s)

- 2.000 HP, 1 Phase, 208/230/460V, 60 Hz, ODP (Open Drip Proof)

- 10" Blower.

- Motorized Back-Draft Damper.

- Curb Mount.

- Curb Insulation Available.

- 24 month parts-only warranty

- Recommended for hood Sizes 4-12

Features

- Sloped Screened Intake with Washable Metal Mesh Filters

- Discharge Temperature Control - 40-90 degree F (4-32 degree C)

- Made in USA

- 3/4"" Gas Line Manifold Constructed in Conformance to ANSI Standards

- 24 month parts-only warranty

- Heavy Gauge Stainless Steel Condensate Pans

Overview

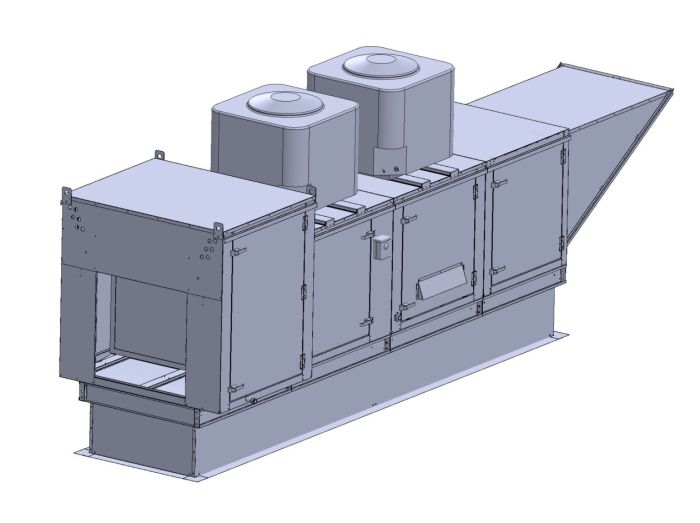

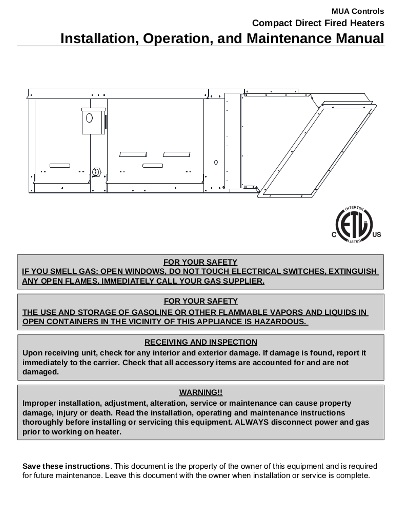

Direct Gas-Fired Heater, for use in tempering make-up air. Packages are certified to the ANSI Z83.4a-2001/CSA 3.7a-2001 combined safety standard. One size is available with a max BTU rate of 270,000 and 1,850 CFM. Housing constructed of heavy duty G90 galvanized steel • Forward curved centrifugal blower wheel • Vibration isolation • Adjustable drive assemblies • Adjustable motor mount • Ball bearing motors • Heavy duty, pre-lubricated bearings rated for 200,000 hours of operation • Service doors on both sides • Horizontal & down discharge • Large intake area ensures low pressure drop across unit • Spring loaded profile plates automatically adjust for any airflow - no manual setting required! • Weatherproof safety disconnect switch • Modular design provides design flexibility • Fully insulated casing With DX cooling, refrigerant flows through the evaporator coils to absorb heat, thus cooling and dehumidifying the air. A compressor moves the coolant through the coils and a condenser removes the absorbed heat for exhaust outside

LET US HELP YOU

How Can We Help You?

What Type of Hood Do You Need?

Experts Are Ready to Help You:

Custom Size Hoods

Ship in 5-7 Business Days.

TK1 - 3PH (1850 cfm) - Direct Gas Fired Tempered Makeup Air Unit/DX

TK1-DX-3PH - DIRECT GAS FIRED TEMPERED MAKEUP AIR UNIT/DX

Gas-Fired Tempered Make-Up Air Unit with Direct Expansion/Maximum 1,850 CFM's, 208/230/460V, 3-Phase with Motorized Damper and a 10" Blower

- Gas-Fired Tempered Make-Up Air Unit with Direct Expansion handles a Maximum of 1,850 CFM's @ 0.5" wg ESP

- Max Temperature Rise of 100 Deg F. 129,600 BTU's, Natural Gas/LP Burner

- 5 Ton, Dual Circuit DX Cooling

- Adjustable CFM Range 1800-1850

- Fully Packaged Unit with 14 SEER Condensing Unit(s)

- 2.000 HP, 1 Phase, 208/230/460V, 60 Hz, ODP (Open Drip Proof)

- 10" Blower.

- Motorized Back-Draft Damper.

- Curb Mount.

- Curb Insulation Available.

- 24 month parts-only warranty

- Recommended for hood Sizes 4-12

Features

- Sloped Screened Intake with Washable Metal Mesh Filters

- Discharge Temperature Control - 40-90 degree F (4-32 degree C)

- Made in USA

- 3/4"" Gas Line Manifold Constructed in Conformance to ANSI Standards

- 24 month parts-only warranty

- Heavy Gauge Stainless Steel Condensate Pans

Overview

Direct Gas-Fired Heater, for use in tempering make-up air. Packages are certified to the ANSI Z83.4a-2001/CSA 3.7a-2001 combined safety standard. One size is available with a max BTU rate of 270,000 and 1,850 CFM. Housing constructed of heavy duty G90 galvanized steel • Forward curved centrifugal blower wheel • Vibration isolation • Adjustable drive assemblies • Adjustable motor mount • Ball bearing motors • Heavy duty, pre-lubricated bearings rated for 200,000 hours of operation • Service doors on both sides • Horizontal & down discharge • Large intake area ensures low pressure drop across unit • Spring loaded profile plates automatically adjust for any airflow - no manual setting required! • Weatherproof safety disconnect switch • Modular design provides design flexibility • Fully insulated casing With DX cooling, refrigerant flows through the evaporator coils to absorb heat, thus cooling and dehumidifying the air. A compressor moves the coolant through the coils and a condenser removes the absorbed heat for exhaust outside

CUSTOM FABRICATOR

CUSTOM FABRICATOR