We use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Learn more.

A Crash Course In In-Line Exhaust Fan Energy Efficiency Codes

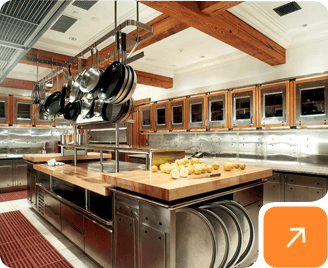

Exhaust fans are required for any kitchen and commercial space, but there are different guidelines and codes that are required based on the application for the exhaust system, the building type, local building codes, and much more. When it comes to fans specifically there are also several different model types - Exhaust Fans, Make-Up Air Fans, Downblast Fans, Hurricane / Seismic Rated Fans, and more - all with their own specific use-case and feature sets. As exhaust fan types and the technology has increased so has the need for more energy efficient fan types. Between the customers wanting a fan set up that costs less per month in energy costs, and the local governments implementing energy efficient standards for environmental reasons, new technology has come to the market that allows for more energy efficient, higher performing exhaust fan systems.

Back in 1975 the US Congress started to pass legislation in the effort to improve energy efficiency due to the increases being seen not only in energy use but the high energy costs. Instead of passing nationwide codes and requirements Congress tasked each state with addressing and establishing energy efficiency guidelines. That same year the commercial building energy standard known as ANSI/ASHRAE 90.1 was created by the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE). This energy standard was put in place in a dynamic fashion, meaning that the guidelines that were set in place are ever changing so that as time goes on and technology gets better the guidelines can change with the times.

While ANSI / ASHRAE 90.1 was the energy standard for commercial buildings, there wasn't a dialed-in standard for fan efficiency. In 2013 the Air Movement & Control Association (AMCA) created AMCA Standard 205, Energy Efficiency Ratings for Fans which introduced FEG, or Fan Efficiency Grades. That same year the US Department of Energy put into place a mandate that requires state energy codes to meet or exceed the current ASHAE 90.1 standard within 3 years of publication, or by 2016. FEG measurements were used to measure fan's aerodynamic ability to convert mechanical power to air power, however it turned out to not be a very accurate measurement for how much energy the fan is actually using. A more accurate energy measurement for fans is the US Department of Energy's Fan Energy Index, or FEI. Introduced in 2011, the FEI was better for measuring fan efficiency since it incorporated the losses to each portion of the fan system - fan motor, drive / speed control, transmission and related parts, and the aerodynamics. In a nutshell FEI is a ratio of the exhaust fan electrical input power vs a control fan electrical input power.

The US DOE halted the FEI guidelines in 2017 but FEI was included in the 2019 version of the ANSI / ASHRAE 90.1, making it the key metric when it comes to meeting building codes, reducing energy costs, future regulatory targets, and more. HoodMart provides our customers with a wide range of walk-in coolers and freezers - as well as all walk-in accessories such as door hinges, kick plates, and light fixtures. HoodMart provides our customers with a wide range of exhaust hood systems - from Compensating (Short Cycle) to Perforated Supply Plenum PSP - as well as all exhaust hood accessories such as no weld Grease Duct, hood filters, canopy hood lights, and curbs. Our walk-in selection offers coolers and freezers from quick ship to custom. If you have questions regarding the purchase of your hood system or walk-in, please feel free to contact one of our experts today by calling us at 1.800.715.1014 or by contacting us through our live chat system.

CUSTOM FABRICATOR

CUSTOM FABRICATOR