We use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Learn more.

Avoiding Common Food Truck Health Code Violations

AVOIDING COMMON FOOD TRUCK HEALTH CODE VIOLATIONS

When you own and operate a food truck, that food truck must remain open and operating at all costs to be successful. You might be pumping out great food, have all your equipment and your physical truck operating at full capacity, and everything overall is running smoothly - but all it takes is one random health inspection to throw a wrench in your gears. Health violations can force you to close up shop for a number of days, so here are some of the common food truck health code violations that trucks get dinged for.

1. FOOD STORAGE

When food is not being prepped or cooked it must be stored securely and safely to ensure proper food safety. Improper food storage is one of the most common food truck health violations due to the ease of overlooking. To properly store food requires proper food storage containers, identification labels and dates, and ideal storage locations on both shelves as well as refrigerators and freezers. Some improper food storage violations include:

Improper Refrigeration Orders - storing refrigerated foods in the wrong order or arrangement, for example you can never store raw chicken on the shelves above other food products.

Improper Storage Labels - everything must be labeled properly with use dates, and anything that is not in the original packaging needs to be properly labeled.

Wrong Containers - when storing foods for your food truck they must be in commercial grade food containers, you can never use residential food containers.

Food Containers On The Floor - you can never store food containers or boxes on the floor of your food truck, kitchen, walk-in cooler, freezer, etc.

2. PERSONAL HYGIENE

It may seem obvious to some, but proper hygiene is a common health code violation that occurs pretty often. You can pick up violations for hand washing, dirty staff uniforms, jewelry, and improper PPE (personal protective equipment). Staff can be violated for any of the following observations during an inspection:

Improper Hand Washing - employees are required to use warm water and soap when washing hands, and must wash for a minimum of 20 seconds. Employees are also required to wash hands at designated hand washing sinks that have proper signage.

Open Beverages / Food - any open food or beverages belonging to employees are required to be stored in designated areas and properly covered by a lid.

Wrong Jewelry + Accessories - employees are not permitted to wear any jewelry - including but not limited to bracelets, watches, and other accessories - and can only wear plain metal rings.

Hairnets or Face Masks - restaurant food handlers are expected to wear a cap or hairnet when preparing foods, and employees must adhere to state and local requirements when it comes to face mask.

3. TIME AND TEMPERATURE CONTROL

Time and temperature control protocols are put in place to keep foods from spoiling - whether it be hot, cold, raw, or cooked foods. Failure to adhere to proper time and temperature control protocols can lead to bacteria growth and contribute to the spread of food borne illness, and therefore must be taken extremely seriously. The seriousness of these protocols is also why health inspectors will be extra stringent when testing, including:

Food Temperatures - insure proper cooking temperatures and times for food that is being freshly cooked, reheated, etc.

Thawing Frozen Goods - any meats, fish, and other thawing goods must not be left out to thaw, and instead need to be thawed in a refrigerator, in cold water, or in a microwave.

Time / Temperature Labels - foods that are being served or displayed without temperature control must be labeled and monitored.

Unattended Foods / Ingredients - food items that are removed from cold storage must be prepped and cooked, otherwise they must go back into cold storage.

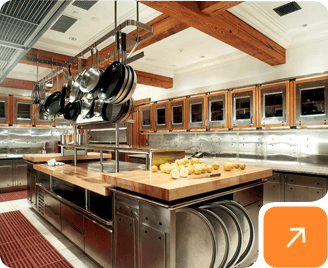

4. KITCHEN SANITATION

Kitchen cleanliness and the overall state of your kitchen word surfaces and equipment is imperative to a successful cooking operation and even more imperative to passing a health inspection. For this reason daily clean ups as well as regular deep cleans are crucial. The visible surfaces are the easiest to clean, however health inspectors love to check the uncommon areas that are less seen as they are the most likely culprit that will lead to a health code violation. Here are some neglected cleaning areas that should be on the top of your regular cleanings:

Bottom Side of Equipment - food debris and buildups happen most common underneath and along the bottom of your kitchen equipment. Daily sweeps and mops of those areas will help to prevent the buildups from occurring, and regularly pulling out the equipment to clean the hard to reach / access areas will help tremendously.

Grease Buildups - wiping down your equipment daily with degreaser can help buildups, but regularly cleaning your grease traps and exhaust hood filters will go a long way.

Other Equipment - other pieces of equipment are susceptible to mold or ‘slime’ buildups, such as ice machine bins and soda fountain nozzles. Daily and regular cleanings will help ensure these pieces of equipment stay clean.

5. CROSS-CONTAMINATION

One of the most important aspects of food safety includes the prevention and avoidance of cross-contaminating foods in your kitchen. Cross-contamination can happen at all stages of the cooking process, from handling and preparing food, to the cooking and food handling after the fact. Unsanitary kitchen environments and mis-use of tools and utensils can also cause cross-contamination. When cross-contamination occurs your put your staff and guests at risk for food-born illnesses and pathogens, chemicals, or even foreign objects, and that is why is it very important to take all steps to prevent cross-contamination, including:

Separate Cutting Stations - you should have different cutting and prep stations for different items. For example, raw chicken should always be chopped and prepped away from vegetables and other food items. Raw meats should be prepped at their own station as well. Once done, these individual stations should be sanitized.

Proper Utensils - using proper utensils with your equipment will prevent cross-contamination and the risk of foreign objects making their way to your guests. For example don’t use any sort of glassware when using your ice bin as scooping ice with glassware could lead to a potential glass chip contaminating the ice. Another example would be storing utensils and tools the ice bin or machine. Any object that is stored in a piece of equipment runs the risk of exposing the contained items to contaminants.

Personal Hygiene - personal hygiene in all aspects of the cooking stages is one of the most effective ways to avoid cross-contamination. Washing your hands after touching raw chicken, meats, and other food prep items at your designated hand-washing station for at least 20 seconds using warm water and soap is a great way to prevent cross-contamination. Using clean towels after washing, and using clean towels with sanitizer to clean up your work station after cooking raw items is another quick and easy way to help prevent cross-contamination.

By having a proper food-safety and cleaning safety plan is the best step you and your food truck operation can take to ensure that you are passing with flying colors whenever a health inspector shows up. Daily and regular cleanings, proper food handling standards, and proper personal and kitchen hygiene will help your kitchen operation stay up and running and your food truck thriving. HoodMart provides our customers with a wide range of exhaust hood systems - from Compensating (Short Cycle) to Perforated Supply Plenum PSP - as well as all exhaust hood accessories such as no weld Grease Duct, hood filters, canopy hood lights, and curbs. If you have questions regarding the purchase of your hood system, please feel free to contact one of our experts today by calling us at 1.855.411.6386 or by contacting us through our live chat system.

CUSTOM FABRICATOR

CUSTOM FABRICATOR