We use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Learn more.

Commercial Kitchen Exhaust Requirement Considerations | Hoodmart

Introduction

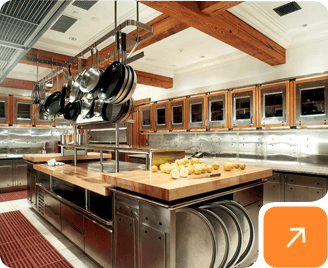

Proper ventilation is crucial in a commercial kitchen to maintain a safe and comfortable working environment. Commercial kitchen exhaust systems play a vital role in removing smoke, grease-laden vapors, and odors generated during cooking. In this article, we will provide a general overview of commercial kitchen exhaust requirements, highlighting their importance while emphasizing the need to consult a professional range hood manufacturer for specific guidelines tailored to your unique kitchen setup.

The Importance of Commercial Kitchen Exhaust and Regulatory Codes

Commercial kitchen exhaust systems are designed to remove airborne contaminants and maintain air quality within the kitchen. They help to prevent the buildup of smoke, heat, and grease, ensuring a comfortable and safe environment for kitchen staff. Because these systems are so vital to health and safety, commercial kitchen exhaust requirements are established by regulatory codes and standards set by local health departments, fire departments, and building authorities. These regulations aim to safeguard against fire hazards, control air pollution, and maintain compliance with safety guidelines.

Ventilation Rate and Air Changes

Commercial kitchen exhaust systems must be designed to provide adequate ventilation rate and air changes per hour (ACH) based on the kitchen size, cooking equipment, and cooking volume. The specific requirements may vary depending on the jurisdiction, kitchen type (e.g., restaurant, cafeteria, or food truck), and the type of cooking performed. An experienced hood manufacturer can help you determine you specific needs through a detailed consult, as most systems will need to be custom tailored to your unique kitchen environment. Proper sizing ensures efficient capture and removal of contaminants, preventing them from spreading throughout the kitchen.

Ductwork Design and Installation

The design and installation of the exhaust ductwork are critical factors in achieving optimal performance. The ductwork must be sized appropriately, free from obstructions, and properly sealed to prevent air leaks. It should also follow the recommended trajectory, taking into consideration the distance, bends, and vertical rise, to maintain sufficient airflow. Each of these factors are subject to specific regulations. Again, working with professionals every step fo the way will ensure that you are informed and working within your local coding and ordinances.

Fire Suppression and Grease-Laden Vapor Removal

Commercial kitchen exhaust systems often require fire suppression mechanisms, such as fire suppression systems or fire-rated ductwork, to mitigate fire risks associated with cooking. Additionally, grease-laden vapor removal devices, such as grease filters or grease extractors, should be installed to capture and contain grease particles before they enter the exhaust system, minimizing the risk of grease buildup and potential fire hazards. Safety regulations and requirment pertaining to fire suppression are typically set forth by local fire code, and may vary from state to state or even county by county. It is important to be aware of the specific requirements based on the location of your commercial kitchen.

Your Local Range Hood Manufacturer is a Valuable Resource in Ensuring Compliance

Complying with commercial kitchen exhaust requirements is essential for the safety, functionality, and compliance of your establishment. While this article provides a high-level overview, it is essential to consult a professional range hood manufacturer for accurate and specific guidelines tailored to your kitchen's unique needs. A reputable manufacturer like HoodMart can assess your kitchen layout, cooking equipment, and local regulations to provide expert advice on the most suitable exhaust system design and installation for your establishment.

CUSTOM FABRICATOR

CUSTOM FABRICATOR