How to Maintain Your Commercial Fire Suppression System for Maximum Safety

- Diciembre 03, 2025

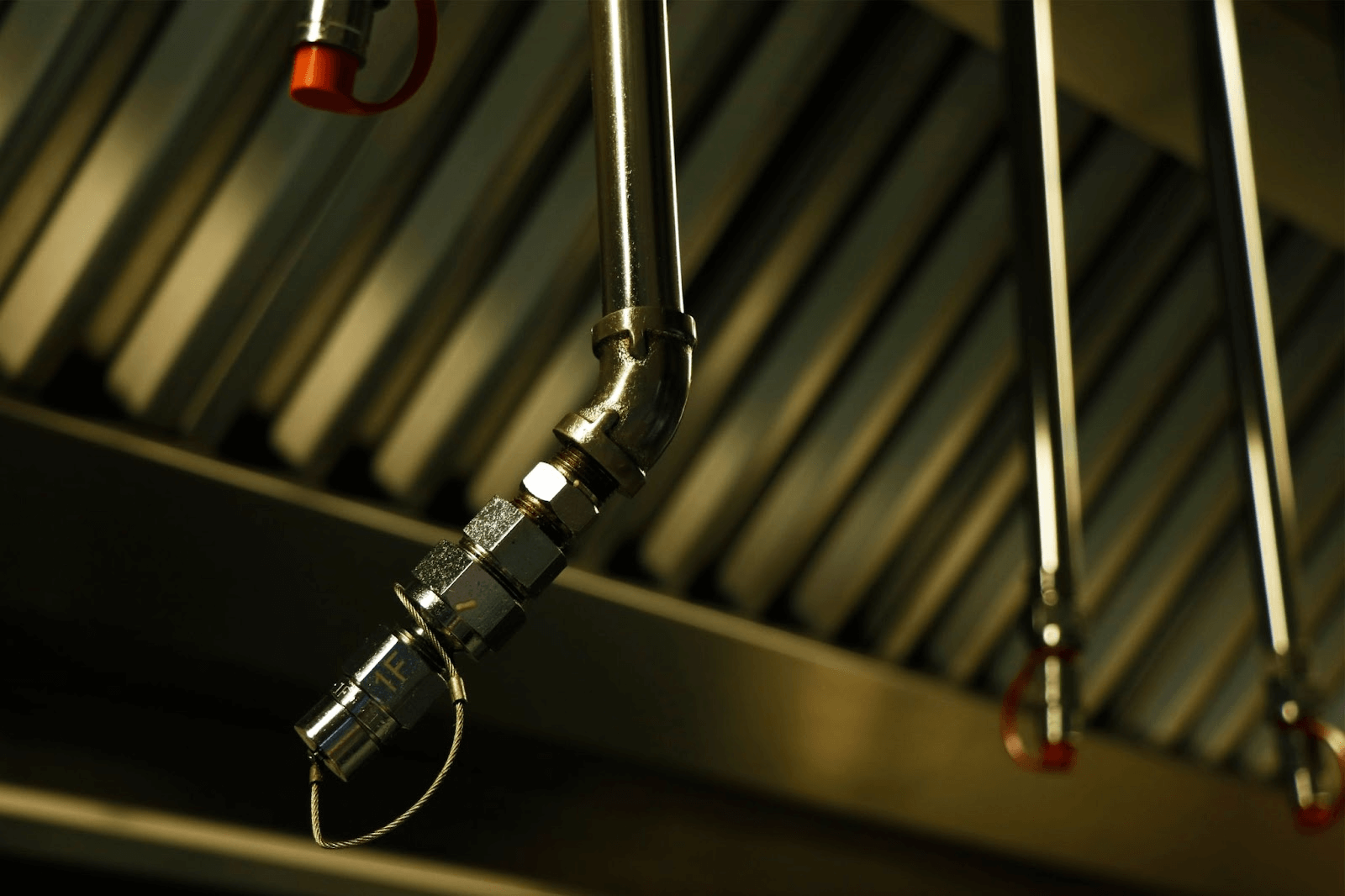

In a busy commercial kitchen, fire risks are a daily reality. High-heat equipment, open flames, and cooking oils can quickly turn a small flare-up into a dangerous situation. That’s why a commercial fire suppression system is one of your kitchen’s most important safety investments.

These systems are designed to detect and extinguish fires automatically—protecting your employees, customers, equipment, and building. But simply installing a system isn’t enough. Regular maintenance and proper care ensure your hood fire suppression system works exactly when you need it most.

This guide breaks down how these systems work, why upkeep is essential, and what steps to take to keep your kitchen safe and code-compliant.

How Commercial Fire Suppression Systems Work

A fire suppression system for commercial kitchens integrates directly with your exhaust hood system. Key components include:

- Detection sensors that monitor heat or smoke over cooking surfaces.

- Control panels that trigger the system automatically.

- Wet chemical fire suppression agents designed to smother grease fires.

When a fire is detected, the system releases the wet chemical agent through strategically placed nozzles above fryers, grills, and ranges. The agent cools the flames, creates a soapy barrier to cut off oxygen, and prevents reignition. Simultaneously, the system shuts off gas and electricity to the affected equipment—minimizing further damage.

Why Regular Maintenance Is Non-Negotiable

Maintenance isn’t just a box to check—it’s what ensures your exhaust hood fire suppression system will work when it matters.

Regular inspections and service help you:

- Ensure functionality: Keep sensors, control panels, and chemical agents in proper working order.

- Meet fire codes: NFPA and local regulations require routine inspections.

- Extend system life: Prevent premature wear and costly replacements.

- Minimize downtime: Catch issues early before they lead to operational disruptions.

Practical Steps to Maintain Your Fire Suppression System

1. Schedule Semi-Annual Professional Inspections

Certified fire suppression technicians should inspect your system at least twice a year—or more often if required by local regulations. They will:

- Test detection sensors for responsiveness.

- Verify that control panels trigger the system correctly.

- Check chemical agent levels and replace or refill as needed.

2. Keep the System Clean

Grease buildup is one of the most common reasons systems fail. Regularly clean hood filters, ducts, and cooking equipment. A clean system ensures sensors and nozzles remain unobstructed and ready to respond.

3. Train Your Kitchen Staff

Everyone on your team should know:

- How to manually activate the suppression system in an emergency.

- Why it’s critical not to block nozzles or cover sensors.

- How to report potential issues immediately.

4. Replace Outdated Components

Over time, sensors and control panels can become less reliable. Periodically review your system to ensure all parts meet current UL 300 wet chemical fire suppression and NFPA standards.

5. Keep Detailed Maintenance Records

Document every inspection, service, and repair. These records help you stay on schedule for future maintenance and are often required during regulatory inspections.

Additional Fire Safety Best Practices

Maintenance goes hand-in-hand with broader kitchen fire safety measures:

- Conduct regular fire drills so staff know how to respond quickly.

- Stay up to date on changing fire codes and update protocols accordingly.

- Integrate your fire suppression system with your overall ventilation strategy to ensure seamless protection.

FAQs: Fire Suppression System Maintenance

Q: How often should a commercial fire suppression system be inspected?

A: At least every six months, or more frequently if required by local regulations.

Q: What happens during a professional inspection?

A: A certified technician checks detection sensors, control panels, and chemical levels; tests system functionality; and ensures code compliance.

Q: Are wet chemical systems required in all kitchens?

A: Yes. Most jurisdictions require UL 300 wet chemical systems for any cooking equipment that produces grease-laden vapors.

Keep Your Kitchen Protected — Request a Quote Today

Regular maintenance keeps your commercial fire suppression system ready to respond in seconds—protecting your staff, property, and peace of mind. HoodMart offers high-quality vent hood fire suppression systems, expert guidance, and code-compliant solutions for every type of commercial kitchen. Contact us for a free quote today!

CUSTOM FABRICATOR

CUSTOM FABRICATOR